SPEEDFLOOR® Systems Offer Superior Spanning Capability

SPEEDFLOOR® New Zealand has produced over 1 million metres of Suspended Floor Joist sections from its Auckland based roll formers.

SPEEDFLOOR® New Zealand has produced over 1 million metres of Suspended Floor Joist sections from its Auckland based roll formers. The companies Suspended Structural Floors Systems have been developed and tested for use in all forms of primary structures meeting the requirements set out in the building code.

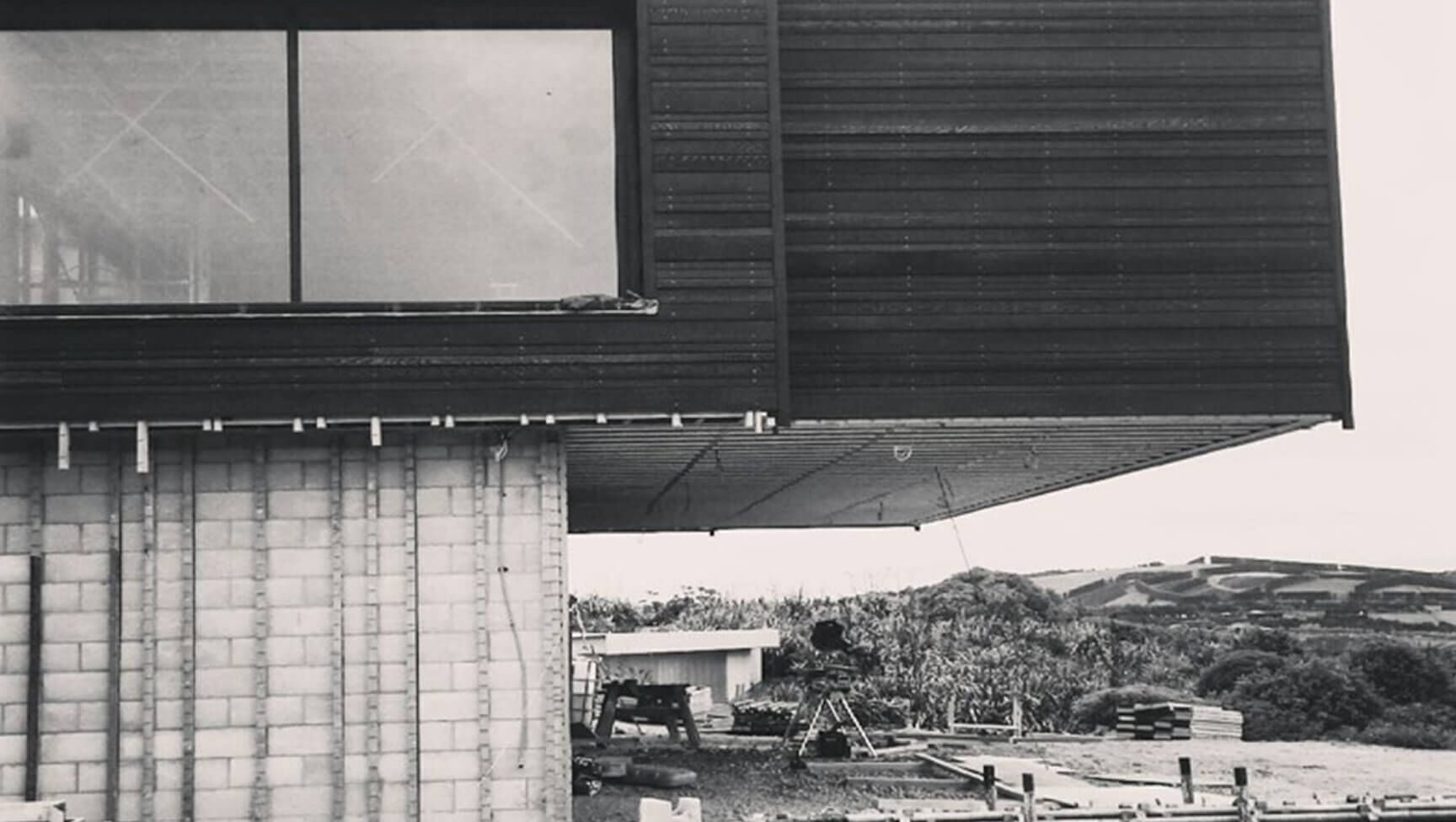

Both the Suspended Concrete Floor and light weight Steel Joist Systems are ideal for offices, schools, industrial and residential applications. The superior spanning capacity of these systems offer architects and engineers a myriad of options to complement their designs.

The lightweight Steel Joist System is manufactured from locally produced galvanized steel coils with designs utilising BIM through detailed shop drawings and modelling ensuring each project is dimensionally accurate minimising time and waste on site.

The Suspended Concrete Floor System offers a clear spanning solution that requires no propping or shore loading during the construction phase and minimizes reliance on cranes or mechanical lifting equipment. It is the environmentally responsible choice given that it would be one of the least users of materials per spanning on a square metre basis.

Both these SPEEDFLOOR® Systems offer simple connection details along with practical solutions for fire and acoustic ratings combined with manufactured service voids to accommodate services within the structural depth of the floor.

All of these benefits combine to provide significant advantages to the construction programme of any project that is lucky enough to have SPEEDFLOOR® specified.

Working with supply partners based in Auckland, Hawkes Bay, Wellington, Canterbury and the Queenstown Lakes District these systems can be sourced and delivered quickly and efficiently saving your project time and money.

This project is also featured as an EBOSS article