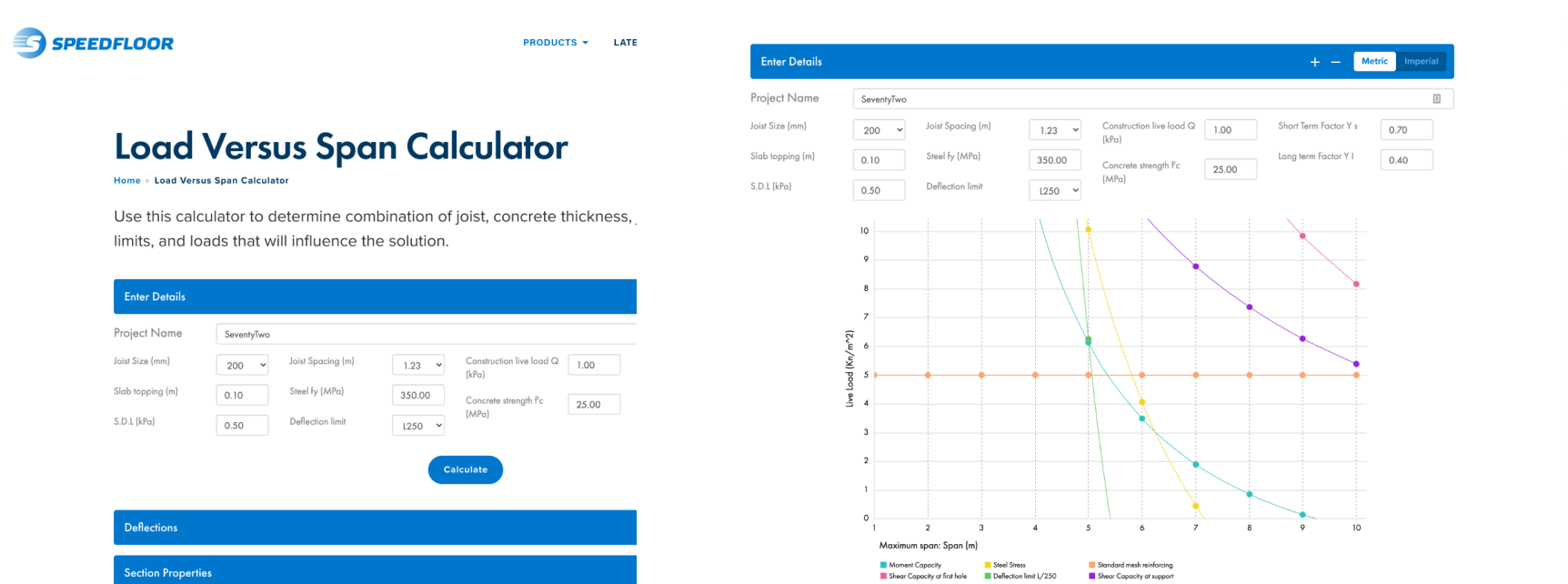

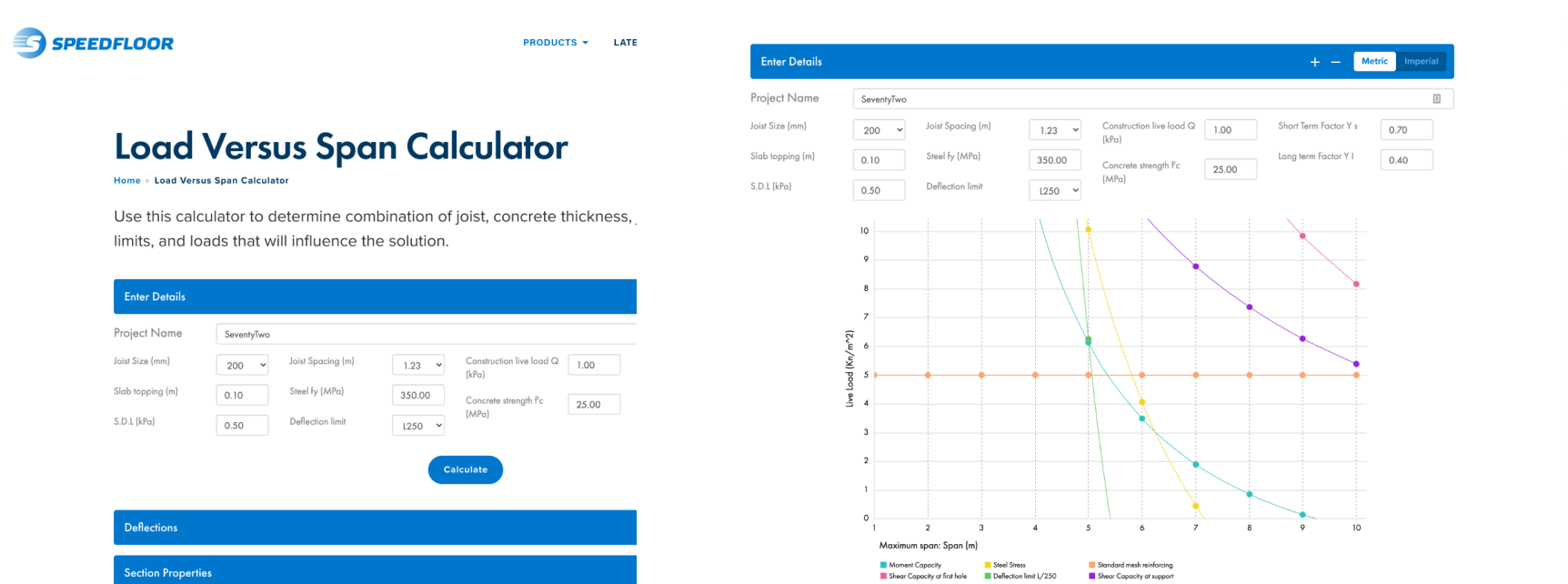

Suspended Concrete Flooring Load vs Span Calculator

Use our free calculator to determine the combination of joist, concrete thickness, joist spacing, deflection limits and loads that will influence the solution that’s right for your project.

When you need a lightweight, high precision floor fast, nothing touches the SPEEDFLOOR® Transportable Concrete Floor for time and cost savings.

Why waste time pouring on site when you can have a perfect, custom floor delivered ready to go? Our unique steel joist system is combined with a roll-formed perimeter channel to create a strong, lightweight, concrete floor with slab topping between 65 to 95mm and maximum steel joist span of 4200mm, that can be manufactured without the cost of a mould.

The Transportable Concrete Floor is an engineered solution for modular offsite, prefabricated residential and commercial applications. It can be used in residential single level sub-floor applications, and has performed well where there is need for mass in the base of buildings without the excessive weight of concrete floor cast in steel mould. The Transportable Floor is a proven solution as a suspended floor such as carparks, and is also ideal where minimal disruption is important.

The roll-formed steel sections ensure dimensional accuracy and are galvanised to 275g/sqm or 450g/sqm. Because the floor requires no mould or formwork, any area can be produced within the limits of the roll-formed sections.

The SPEEDFLOOR® Transportable Floor meets New Zealand Building Standards and under normal conditions, can be expected to meet the durability performance criteria set out in the New Zealand Building Code for a period of 50 years.

Use our free calculator to determine the combination of joist, concrete thickness, joist spacing, deflection limits and loads that will influence the solution that’s right for your project.

You must first confirm that your engineer or architect has access to a Transportable Floor Product manual which can be obtained from your local SPEEDFLOOR® franchise or from this Website. Armed with span, design loads (live, point and line loads) and any openings in the floor, he may then select from the appropriate load span tables, a joist and topping combination.

There are a number of publications where this information is available but our recommendation is firstly the New Zealand, code AS/NZS 2312:2002 Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings, and then further information from the HERA Report R4 -133:2005

The concrete thickness can be varied from 65mm to 90mm and this will have the major impact on the floor weight. You should contact your local SPEEDFLOOR® franchise for a comprehensive weight of a complete transportable floor. Light weight concrete such as Litecrete or cellular concrete can also be used but the concrete must obtain a minimum strength of 15 MPa at 28 days.